How Hesus reduces full-truckload transportation costs by 14% with Hexaly

Hesus leverages Hexaly Optimizer inside a full-truckload (FTL) transportation optimization solution and reduces its transportation costs by 14%. As a European leader in sustainable solutions for the management of construction site soil, the group is positioned in all strategic, operational, and logistical areas of expertise with proven expertise in polluted sites and soils. They assist all players in the construction and public works sector during the design, construction, and demolition of infrastructures and buildings. Present in six countries, they manage the transportation of nearly 2 million tons of soil each year in France and Europe and recover an average of 82% of the spoil on their sites.

A challenging full-truckload transportation problem

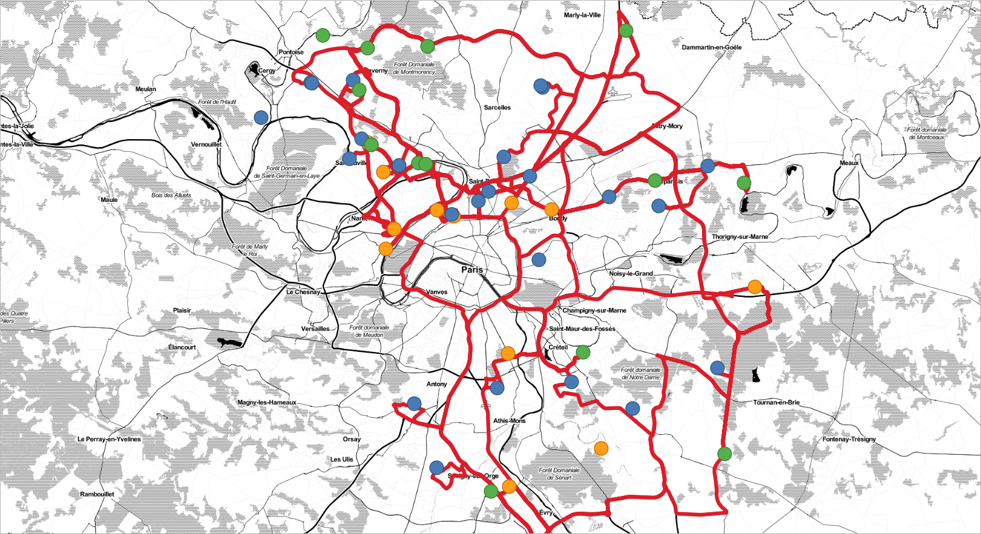

Dozens of construction sites delegate their transportation logistics for excavated earth and construction materials daily to Hesus. Transport infrastructure or building sites require the movement of large quantities of excavated soils and building materials. The ground extracted from these construction sites can present different pollution levels, requiring specialized center treatments. Once the treatment has been completed, the inert soil obtained can be reused as backfill for earthworks, while the extracted materials, such as gravel, can be used as raw material for other construction sites. The different trips needed to move these materials and the operational constraints lead to a difficult Vehicle Routing Problem (VRP). In addition to the traditional constraints of a VRP, it is necessary to consider the road traffic, the opening hours of construction sites and treatment centers, and specific regulatory constraints such as the maximum driving time and break times to have the most realistic routes possible. Mathematically speaking, this problem is related to a Vehicle Routing Problem (VRP) with full truckloads (FTL). The main objective is to reduce as many empty trips for dump trucks, in other words, unproductive minutes and kilometers for the whole fleet of trucks.

More than 300 tours are requested per day for evacuations/deliveries. This represents 10,000 tons of material to be moved between construction sites and treatment centers.

Hesus Dispatch solution

The resulting transportation optimization solution based on Hexaly Optimizer as the core optimization engine, called Hesus Dispatch, optimally matches possible drop-off locations with potential loading sites along the truck routes while respecting all their operational constraints. Thus, Hexaly allows Hesus to reduce its transportation costs and carbon footprint of truck journeys by 14%.

The optimization engine can identify how to efficiently mutualize a truck across several sites and treatment centers to reduce the length of empty transition rides between valuable trips. For instance, it can lead a truck to evacuate excavated soils from a site to a treatment center further than the nearest ones but close to another site with transportation needs. The extra distance traveled to reach this treatment center will be more than compensated by the short deadhead ride to move to another site where the truck will be reloaded to continue its journey. Identification of efficient repositioning among the numerous possible combinations resulting from the size of the problem is one of the levers used by optimization to improve operational efficiency.

Another improvement comes from a better filling of trucks timetable, which reduces the number of trucks needed to perform the transportation. The engine will exploit differences in sites and centers’ opening hours to increase the used time range of the truck with respect to regulatory constraints. The effective time range of a truck can also be increased by tweaking the end of the truck roadmap to avoid returning too early to the truck depot. For example, at the end of a day, a truck may evacuate soils from a site to a nearer center than the one used during the rest of the day. This nearby center can be less attractive in terms of treatment costs than the others but allow an extra tour to be planned at the end of the day, a tour which is not possible for other treatment centers due to daily travel time limitation.

Finally, the optimization engine chooses the most suitable contractors for truck providers and treatment centers regarding geographic implantation and prices. The tradeoff is indeed challenging to find for a planner at hand. Choosing the truck depots and processing centers closest to the sites reduces the distance traveled, but it increases the overall cost as those contractors close to sites are located in urban areas and thus generally expensive. On the contrary, choosing the cheapest contractors will increase the distance as they are located far from the sites, resulting in a higher number of trucks and an important transportation cost despite a reasonable unit price.

To ease the change management and the adoption of the decision-support tool by the logistic planners, Hesus Dispatch allows fine control of the complexity of the routes generated by the engine.

Environmental impact

Because the excavated soil from one site can become a resource for another, Hesus, Greentech’s partner for construction sites, puts the circular economy at the heart of its solutions. They favor reusing soil and materials while ensuring soil compatibility and preventing contamination risks. Hesus prioritizes the reuse of soils, which allows controlling costs while acting to preserve resources and reduce CO2 emissions. Hesus partners with more than 900 sectors, including treatment and decontamination centers, quarries, and storage facilities. Thus, each site benefits from a service adapted to the type of pollution of its soils and waste. In 2020, Hesus achieved an average recovery rate on its sites of over 84%. Mathematical optimization has proven to play a significant role in solving Hesus’ challenging transportation problem both from an operational and environmental point of view. That’s why the Hexaly team is glad to help Hesus’ team achieve even more ambitious goals in the years to come.

The optimization engine helps me every day to dispatch our customer orders. On top of saving me a lot of time that I can dedicate to other high-value-added tasks, it is exciting to discover each day how the routes can be optimized and contribute to sustainable solutions for construction site soils.

Please look at our customers‘ webpage to discover more industry case studies. Are you interested in trying it out? Get free trial licenses here. In the meantime, feel free to contact us; we will be glad to exchange about your optimization problems.