How Hexaly solves Renault Group’s workspace allocation problem in seconds

Renault Group is a French multinational automobile manufacturer and one of the largest automakers in the world. They have been using Hexaly Optimizer since 2016 to solve their various optimization problems. In this case, Renault’s Operations Research department sought to optimize workspace allocation problems with Hexaly.

Renault’s workspace allocation problem

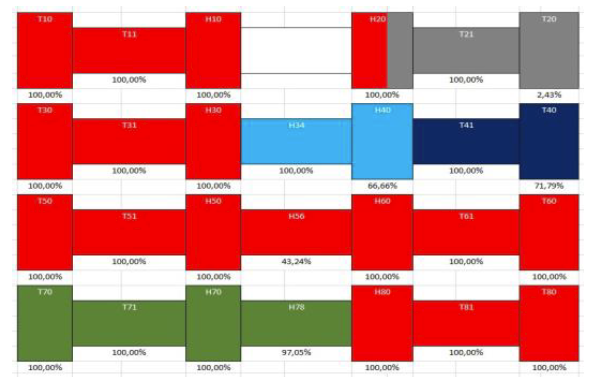

To optimize the organization of its staff in buildings, the Renault team divides the problem into two stages. The first step is macro zoning. It consists in allocating workspaces to Renault’s various departments. The next step is to assign the desks to people; it’s called micro zoning.

Here is an overview of the optimization model to be solved by Renault Group:

Input data

- 5 departments

- 27 workspaces

- 1109 people

Decisions

- Allocate workspaces to departments

- Assign desks to people

Constraints

- Respect the capacity of the modules

- Assign all staff members

- Reserve some modules for departments (modules with specific equipment)

- Departments requiring a high degree of confidentiality must not share their modules with other departments

Objectives

- Smooth the filling rate of the different modules

- Group members of the same department in the same module or neighboring modules

- Group services from two departments collaborating closely in the same module (or neighboring modules)

- As much as possible, assign a single department to a module

Why Hexaly?

The workspace allocation problem is hard to solve because of the coupling of matching and packing constraints, as well as the multiple nonlinear objectives to optimize. For example, smoothing the filling rate of the different modules induces quadratic expressions. Despite its hardness, Hexaly provides near-optimal solutions in less than 1 minute of runtime. In addition, the intuitive and powerful modeling language offered by Hexaly, namely LSP, allowed the Renault OR team to develop the mathematical model in just a few hours.

We use Hexaly Optimizer for several optimization problems, including scheduling door manufacturing in car factories and optimizing empty packaging return flows. What we appreciate most is the incomparable ease of modeling provided by Hexaly formalism. Besides, exchanging with the Hexaly team is always fruitful and pleasant.

Please look at our customers‘ webpage to discover more case studies in various industries. Are you interested in trying it out? Get free trial licenses here. In the meantime, feel free to contact us; we will be glad to exchange your optimization problems.